Benefits Of A 4-Axis Rotary Table

Rotary tables are necessary for milling workpieces that require complex cuts, with some parts requiring a 4-axis rotary table. Some shops may find that one is never required, depending on the nature of your shop's production. However, many shops will find that a 4-axis rotary table is occasionally needed.

While some operators are talented enough to creatively program a 3-axis rotary table or mill - or, with ever-diminishing frequency, make complex cuts by hand - the 4-axis rotary table has too many benefits to not consider adding one to your current equipment inventory if you currently lack one.

A Rotary Table Expands Your Milling Capabilities...And Efficiency

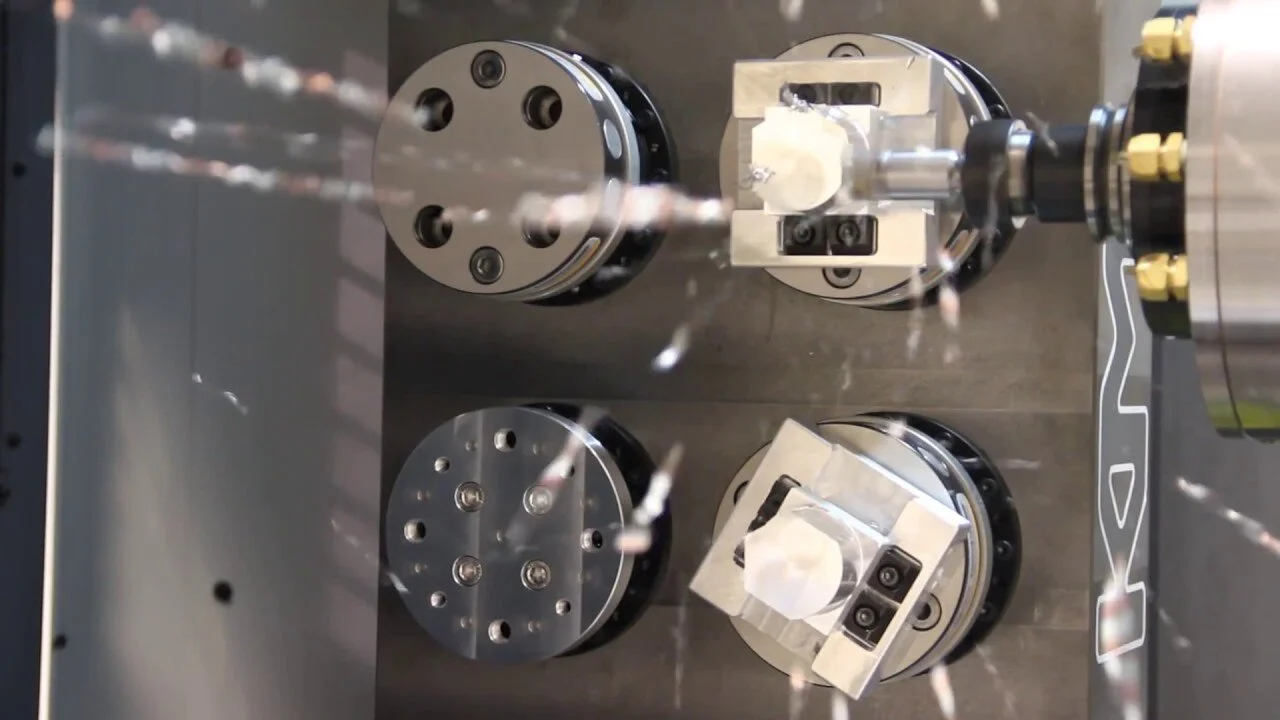

By adding additional axes of rotation, a rotary table with 4-axis (or even 5 Axis CNC systems) capabilities drastically increases the complexity of parts that your shop is capable of producing in many cases, and makes the process far more efficient.

With only three axes of rotation, the operator has to program the workpiece in stages, pausing to unclamp and reposition the workpiece until the necessary cuts have been made. This adds production time.

A 4-axis rotary table rotates the workpiece during the machining process, allowing the operator to program more cuts - if not all cuts - so the part can be milled from start to finish without requiring unclamping or repositioning.

While some shops can afford in some instances to take longer to produce some parts, most shops can ill afford to spend longer on machining any part for longer than is necessary. For the job shop, product not going out is revenue that is not coming in.

There is a place for slow craft, with time taken to produce work that is made slowly and with amazing exactitude for the sheer sake of perfection in a craft. However, the modern machine shop is not that kind of operation.

Unless complex part orders are a rare occurrence for your shop, taking unnecessary time to reposition workpieces several times during machining is not a sustainable or efficient practice. Therefore, a 4-axis rotary table makes your machine shop more efficient.

Applications For 4-Axis Rotary Tables

There are a number of applications for which 4-axis rotary tables are perfectly suited.

Any part that requires tapping equidistant holes around 360 degrees of the work piece typically require multiple repositionings to be fully finished. A 4-axis rotary table allows this to be done in one sitting; program your mill and the table and no more stoppages are necessary.

Any similar task requiring the same cut made around 360 degrees is likewise made easy with a 4-axis rotary table; arc cuts, curved contours and grooves are also made far simpler. Gear teeth are another example of complex cuts requiring multiple position changes that are made far faster and more accurate with a rotary table with 4-axis capability.

Given that the complexity of parts and speed with which they can be manufactured is so drastically amplified, a 4-axis rotary table is an absolute must.

ATS Systems has many Automation Systems available for your machine shop as well.