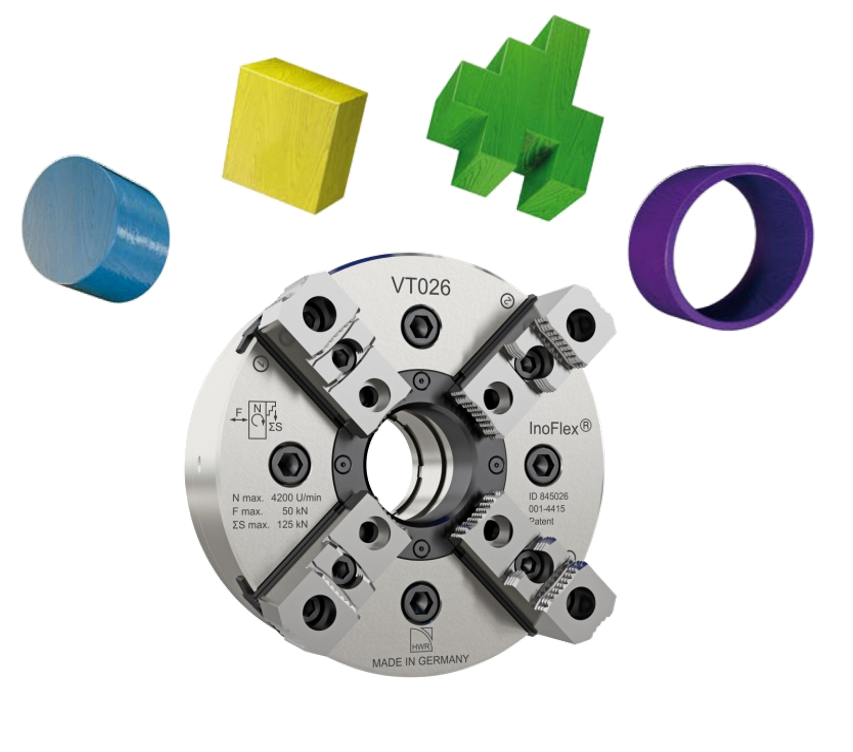

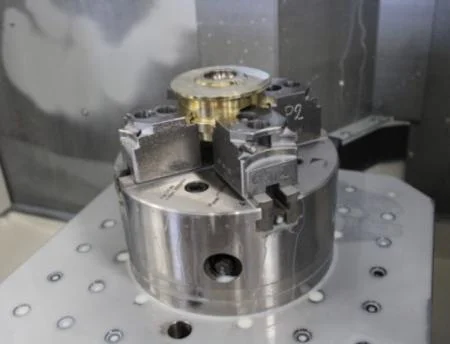

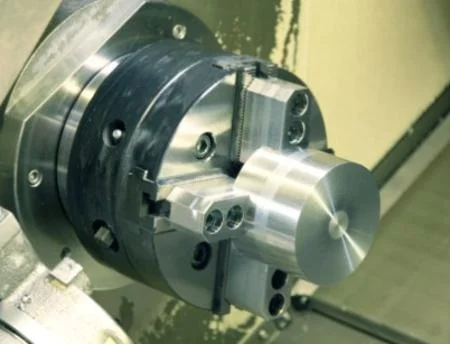

InoFlex - Concentric and compensating 4-jaw chuck

The most versatile and innovative chuck on the market. Available in manual & hydraulic.

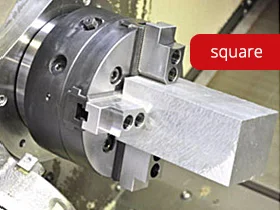

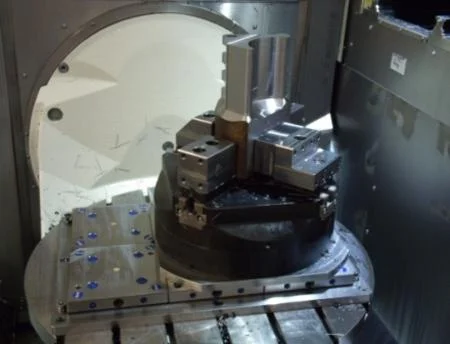

The trend is towards combined turning and milling machines for both round, rectangular and geometrically irregular parts. In the past, companies have used rigid concentric 3-jaw chucks for clamping round parts and worked with vices (two jaws) for rectangular and geometrically irregular parts.

HWR has reacted to this development and produced the first universal clamping tool for clamping round, rectangular and also geometrically irregular parts. With the patent application dated January 2013 for the concentric and compensating 4-jaw chuck InoFlex, HWR is launching a clamping tool to perform this task in a range of Ø 160-1200 mm. No other clamping tool on the market can do this!

Type VD

Manual chuck

without through-hole

Type VK

Power chuck

without through-hole

Type VT

Power chuck

with through-hole

Type VL

Manual chuck

(weight reduced)

To purchase, or for more information

InoFlex® offers you the following advantages:

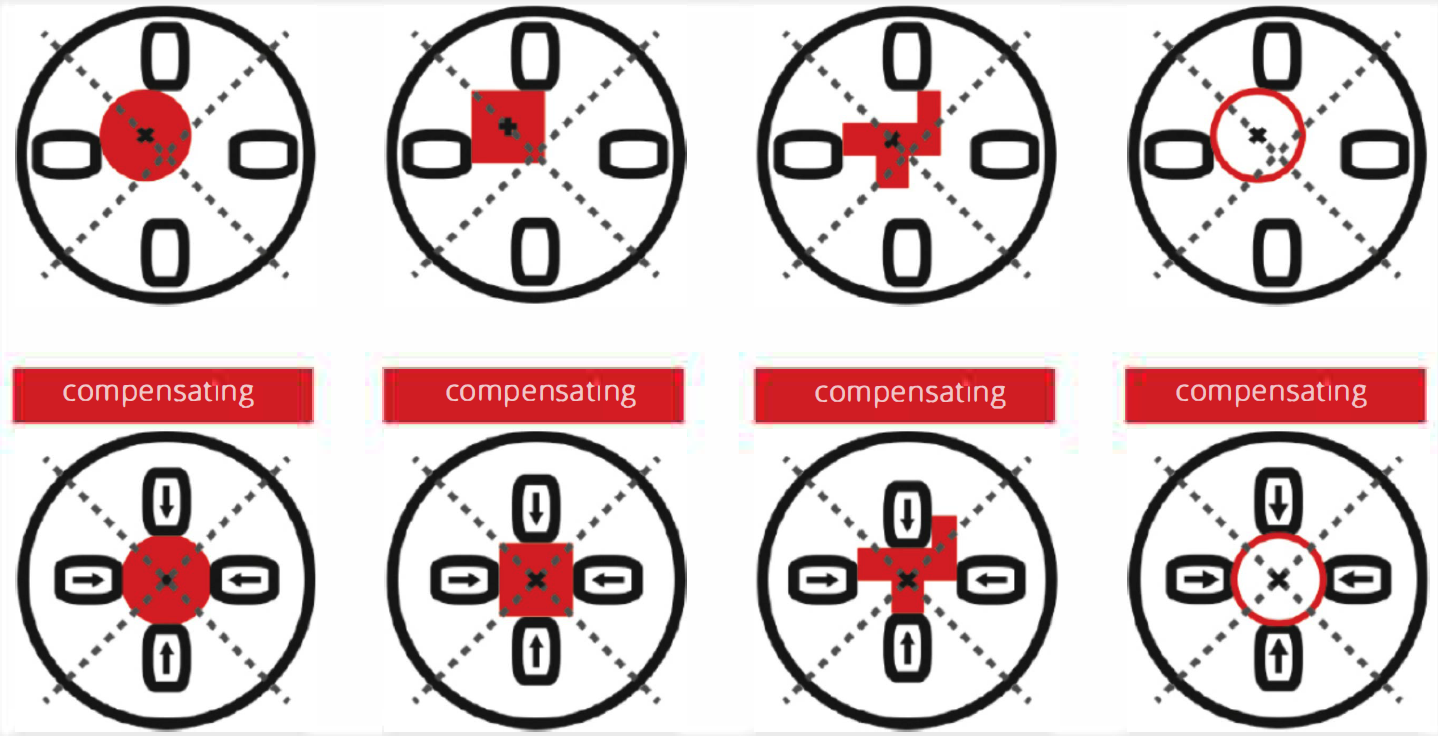

4 Jaws For Compensating Clamping

For concentric and compensating clamping

For clamping of round, cubic and geometrically irregular parts

Suitable for deformation-sensitive workpieces

Low-Cost All Around

Can be used on all modern machine tools

Available as manual chuck Ø 160-1200 mm

Available as power chuck Ø 210-1000 mm

No expensive special clamping solutions needed

High Repeat And Roundness Accuracy

Precise production results confirmed in practice

InoFlex – for the concentric and compensating clamping of round, rectangular and geometrically irregularly shaped parts.

How it Works

In a conventional chuck, all drive parts move in the same direction around the center (e.g. wedge bar, wedge hook, scroll) either towards or away from the center.

The drive of the I no Flex® 4-jaw chuck (concentric compensation) moves towards or apart on two parallel axes. Compensation is provided by connecting the diametrically arranged slides with levers or a sliding gate-type gear.