Ultimate Chuck™

Model UC2

High performance quick jaw change chuck for the shop running small batches

High performance quick jaw change chuck for the shop running small batches

The Solution for First Operation Chucking

A few sets of jaws quickly adjust to cover a wide diameter range

Change, adjust or reverse all three jaws in one minute

1/4 turn wrench, no T-nuts or bolts

Adjust hard jaws in and out to any diameter

Only three sets of "Deep Bite Job Shop" hard jaws cover full grip range OD and ID

Stop using inadequate grip soft jaws for roughing operations

"Deep Bite Job Shop Jaws" transmit torque for maximum metal removal

Model UC2 B-Model

Model UC2B allows using existing custom wide top jaws

Optional master base jaws available to fit common serrated and T&G top jaws

Note: the High Performance jaw system of the UC2 is not available for the UC2B

Better for vertical lathes with O-ring seal to prevent coolant entering between drawtube and spindle bore

Full custom packages installed on your lathe by ATS engineers

Two year warranty with ATS installation

Supported by local ATS Service Technician through the life span of the chuck.

Optional High-Low hydraulic systems available

The Solution for Second Operation Chucking

Eliminate Soft Jaw Reboring

Save 45 minutes of changeover downtime

Bore jaws only once, store for weeks or months, reinstall with 0.0005" TIR guaranteed without reboring

(7" to 12" chucks, 16" chuck 0.0007" TIR)

Monoblock Soft Jaws

Double ended - bore each end for a different part

Premium alloy steel - lasts much longer

No bolts to interfere with gripping surface

Quick change

Additional Benefits

Ultimate Chuck™ wedge bar design allows 25% higher spindle speeds

Ultimate Chuck™ maintains 65% of starting grip force at maximum rated RPM.

Common chucks maintain only 30% even at their lower rated RPM

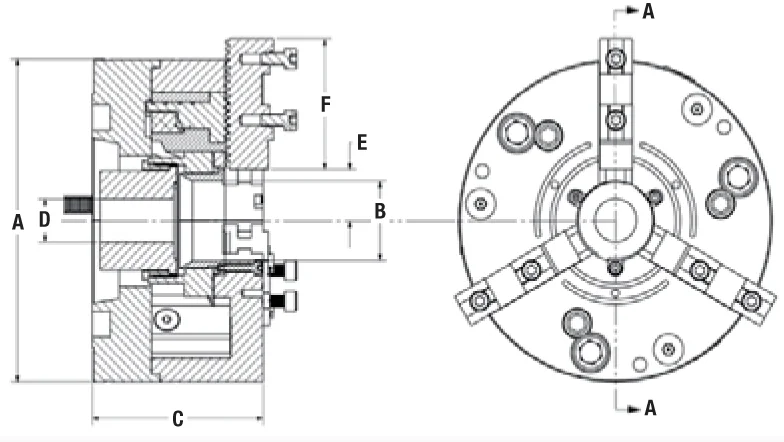

Ultimate Chuck Dimensions

| NOMINAL CHUCK SIZE | 7” | 8” | 10” | 12” | 16” | 20” | 25” | |

|---|---|---|---|---|---|---|---|---|

| Model UC2 | 180-53 | 215-66 | 260-81 | 315-104 | 400-128 | 500-155 | 630-167 | |

| Chuck outside diameter | A | 7.09 | 8.46 | 10.24 | 12.40 | 15.75 | 19.69 | 24.80 |

Through hole |

B | 2.09 | 2.59 | 3.18 | 4.00 | 5.04 | 6.10 | 6.57 |

| C | 4.13 | 4.68 | 5.43 | 5.75 | 6.14 | 7.08 | 7.07 | |

| (UC2B) C | 5.89 | 5.89 | 7.24 | 7.19 | ||||

| Direct mount spindle sizes | A5, A6 | A6, A8 | A6, A8 | A8, A11 | A11, A15 | A11, A15 | Z-520 | |

Max. thread with adapter |

D | M60 | M75 | M90 | M100 | M138 | M170 | M180 |

| E max | 1.63 | 1.93 | 2.04 | 2.54 | 3.40 | 3.97 | 4.74 | |

| F | 2.56 | 3.35 | 4.09 | 4.52 | 4.92 | 6.29 | 7.87 | |

| (UC2B) F | 4.72 | 5.83 | 6.53 | 7.99 | ||||

| Piston stroke - max | 0.83 | 0.94 | 1.10 | 1.10 | 1.18 | 1.38 | 1.57 | |

| Stroke per jaw - max. |

0.27 | 0.30 | 0.35 | 0.36 | 0.39 | 0.45 | 0.50 | |

| Stroke per jaw with most commoncylinder stoke* | *see note | 0.23 | 0.28 | 0.31 | 0.30 | 0.30 | 0.45 | 0.43 |

| Jaw adjustment pitch | 0.19 | 0.19 | 0.22 | 0.22 | 0.22 | 0.28 | 0.28 | |

| Drawbar pull - max. | lbs. | 7,400 | 11,900 | 16,410 | 22,480 | 29,900 | 39,000 | 39,000 |

| Total grip force | lbs. | 13,480 | 22,480 | 30,350 | 40,466 | 53,954 | 68,000 | 68,000 |

| Max RPM - UC2 | 6,300 | 6,000 | 4,700 | 4,000 | 3,500 | 2,200 | 1,700 | |

| Max RPM - UC2B | 2,800 | 2,450 | 1,400 | 1,000 | ||||

| Weight without jaws | lbs. | 39 | 54 | 110 | 161 | 269 | 518 | 926 |